SMART | WORKMAN

Work Management and Service Tracking

Overview

The WORKMAN™ Service Management System (formerly EZ-Service) supports Manufacturing, Maintenance, Repair, Calibration, and IT Service Management (ITSM) whether performed in the field, in-lab, or by a vendor. Service request and ticket tracking, work orders, scheduling, and email notifications are all built in. Unlimited work history includes labor hours, labor cost, and material cost as well as test and environmental readings, and attached documents or photos. With AssetSmart's automatic inventory feature, each service event (PM, repair, etc.) automatically updates the asset system. WORKMAN™ is also the only calibration management application with a fully integrated government property management system, ideal for aerospace & defense contractors or DoD programs with calibrated test equipment, instruments or sensors.

Benefits

- Streamlines compliance with ISO 17025 and 9000/9001, ANSI/NCSL Z540, DOD DFARS, NASA, FAA and other maintenance, calibration, quality, and traceability standards

- Ideal for federal contractors and MRO depots as it seamlessly integrates with the leading SMART | PEMS, TMAS, TRAXX, and EZ-Move Modules

- Leverages common nomenclature, location and user data for assets

Screenshots

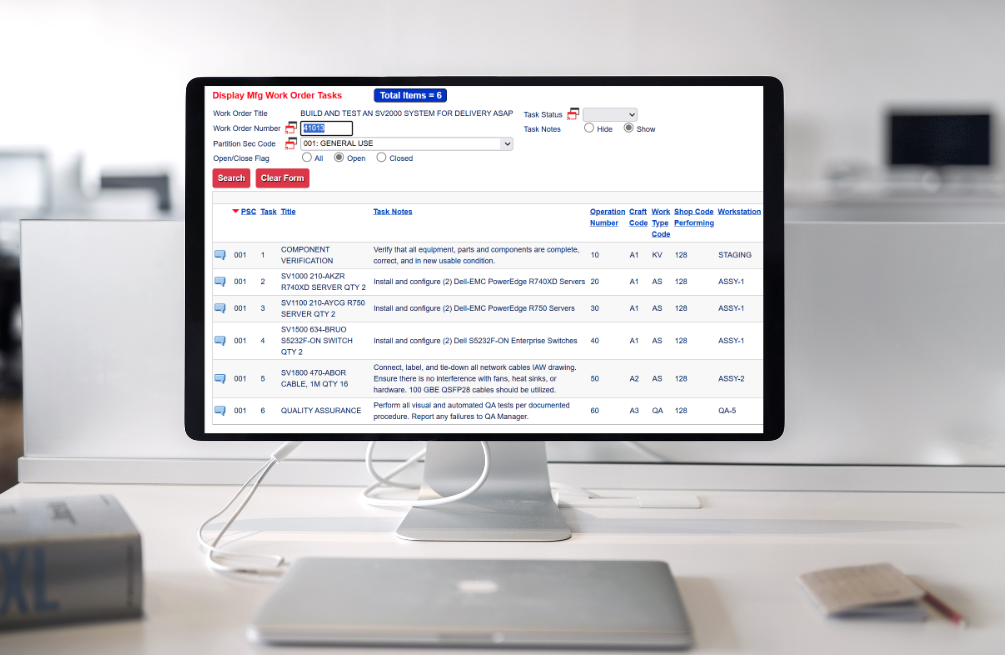

| WORKMAN's powerful work order management features enable tracking of detailed routing or labor tasks for any types of assembly, prototyping, maintenance, or overhaul work. Task-by-task status visibility and planned vs actual labor times and cost metrics are captured. |

Key Features

- Supports planned/scheduled service (Cal, PM), unplanned repairs, or other one-time jobs, and manufacturing assembly or overhaul

- Flexible scheduling types and units for planned service (calendar & usage-based)

- Manages maintenance and calibration procedures and standards required

- Configurable workflow management, email alerts, and barcode labels

- Unlimited history including labor, parts/materials, equipment or standards used, test results, environmental conditions, and uploaded documents

- TRAXX iOS & Android companion mobile app for phones, scanners or tablets

Want to learn more about this product?